Project Specifics

Hagler Systems’ massive floating dredge dubbed “the Kraken” is designed to tackle one of the toughest challenges oil sand producers such as Suncor Energy face: faster reclamation of tailings ponds. Tailings are a mixture of fine clay, sand, water and the residual bitumen that is produced through oil sands extraction. Suncor Energy Inc’s tailings reduction operation incorporates the capture of mature fine tailings drying (MFT) from its tailings ponds in Fort McMurray, Alberta.

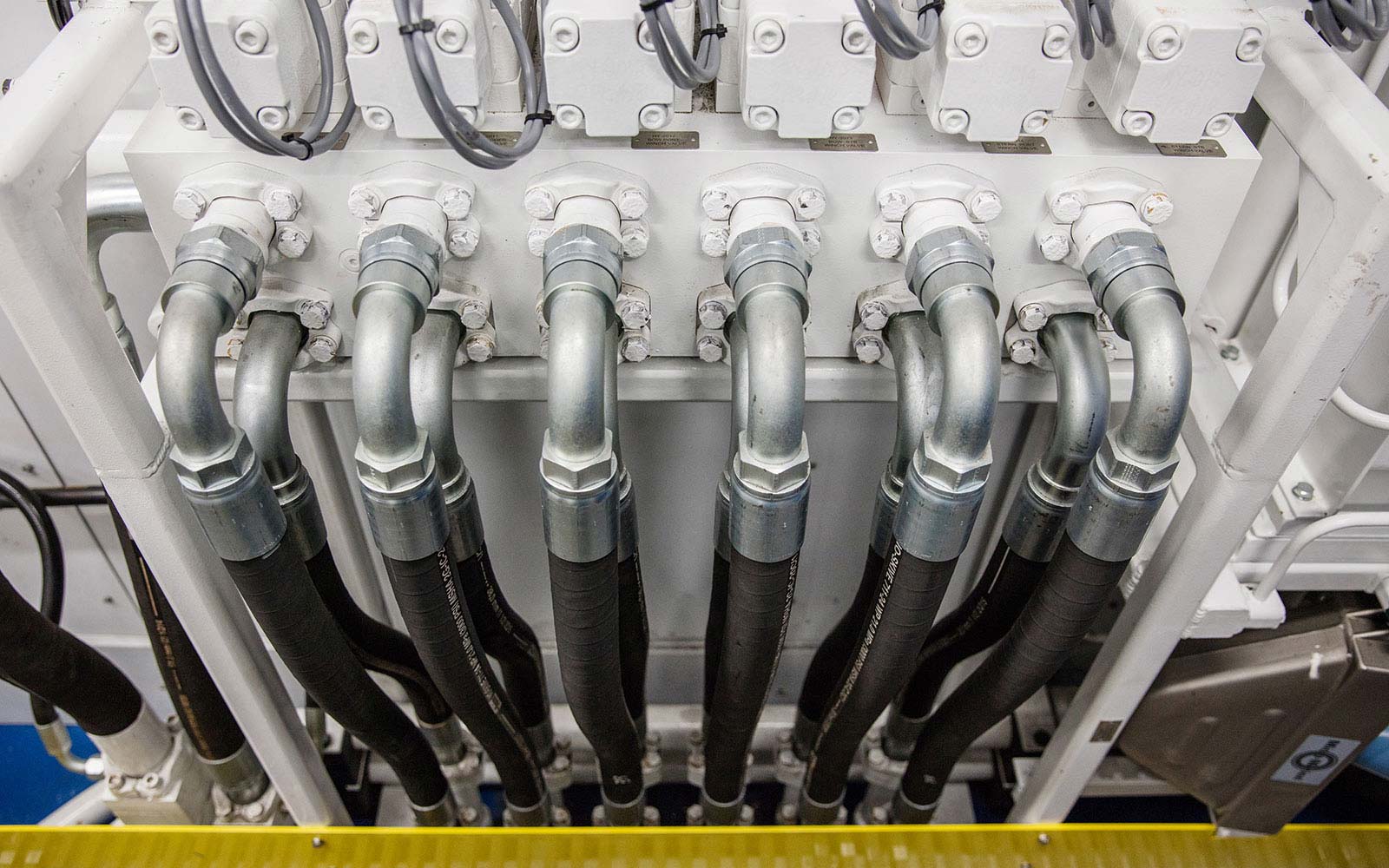

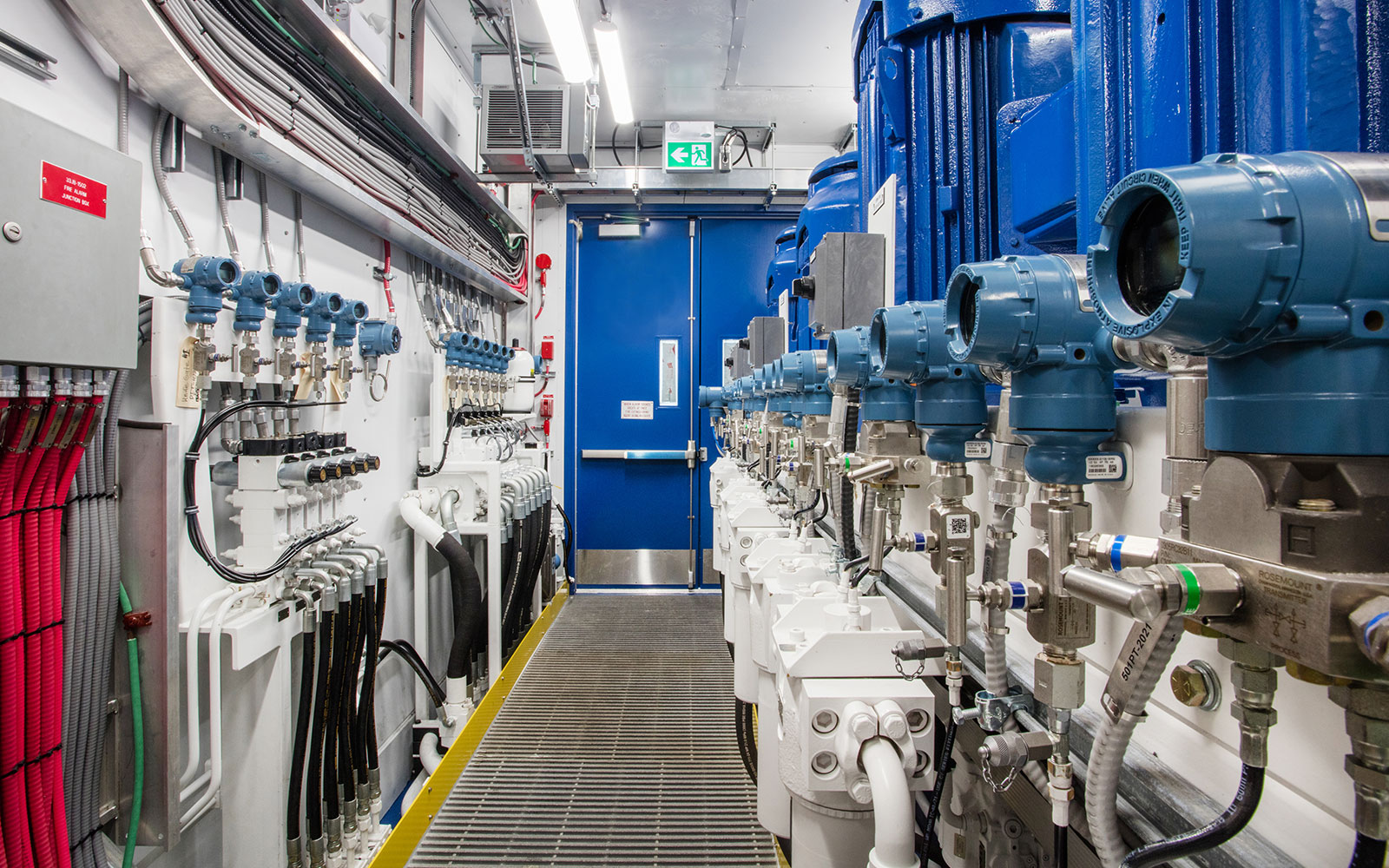

If left untreated, the continuous production from the oil sands will result in an increasing MFT inventory, and therefore an increasing need for additional tailings ponds. At 860 M Tons and 52.5m x 17.5m, the Kraken is by far the largest dredge designed to date that will pump refined tailings from the bottom of a pond. Two Sonic supplied E-houses contain the electrical and hydraulic equipment required to operate the Kraken.

Combining the Hydraulic Pump Unit (HPU) with the MCC rooms was a challenge on this project. It reduces the site works and makes the interconnection and commissioning of the whole system easier at the site. It could also make it possible to do a pre-commissioning of the whole control and instrumentation system before the shipment at the assembly shop. Due to the size of equipment in each room, we had to make an about 84’ long building. We designed the HPU and MCC portion in a 70’ long section to achieve the client request. We performed a transport analysis to make sure that our solution is practical. In addition, since the project was a design-build concept, we encountered numerous late changes and revisions of the drawings. We incorporated a modular package execution strategy to mitigate the effect of the changes and holding points. We were also very flexible on scaling resources when required.

- Versed with rigorous Suncor specifications & standards.

- Multidisciplinary capabilities enable Sonic to easily accept additional scope of work.

- Performed Transport & Logistics route study & risk mitigation strategic plan.

- Coordination of several 3rd party contractors to assist in completion.

- Leveraged Sonic Tier 1 vendors to expedite the project timeline.